1

Racing Mower Builds / German Racing Mower for 13 HP Super-Standard class

« on: May 23, 2017, 07:43:01 am »

Here is my new mower for the 2017 season of 13 HP Super-Standard class according to www.ERWM.de-rules. It nearly runs.

Specs

Chassis: 20x30x1.5 mm and 20x20x2 mm steel profiles for structural beams, 20x20x1.5 mm for support frame parts

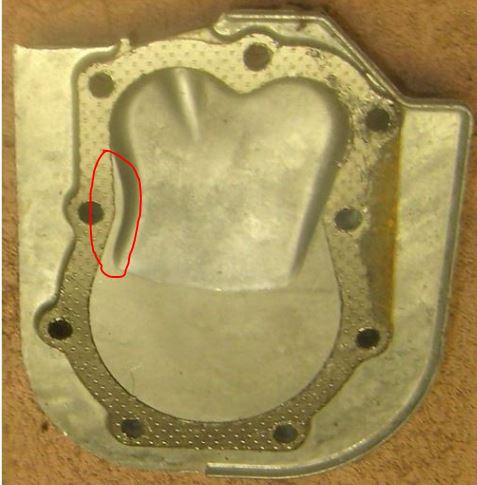

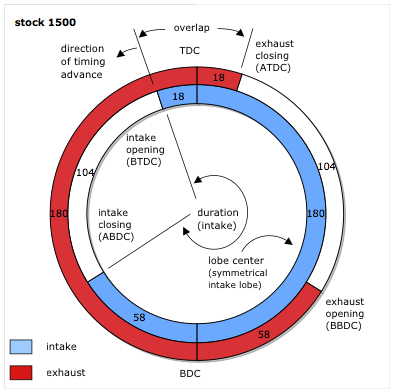

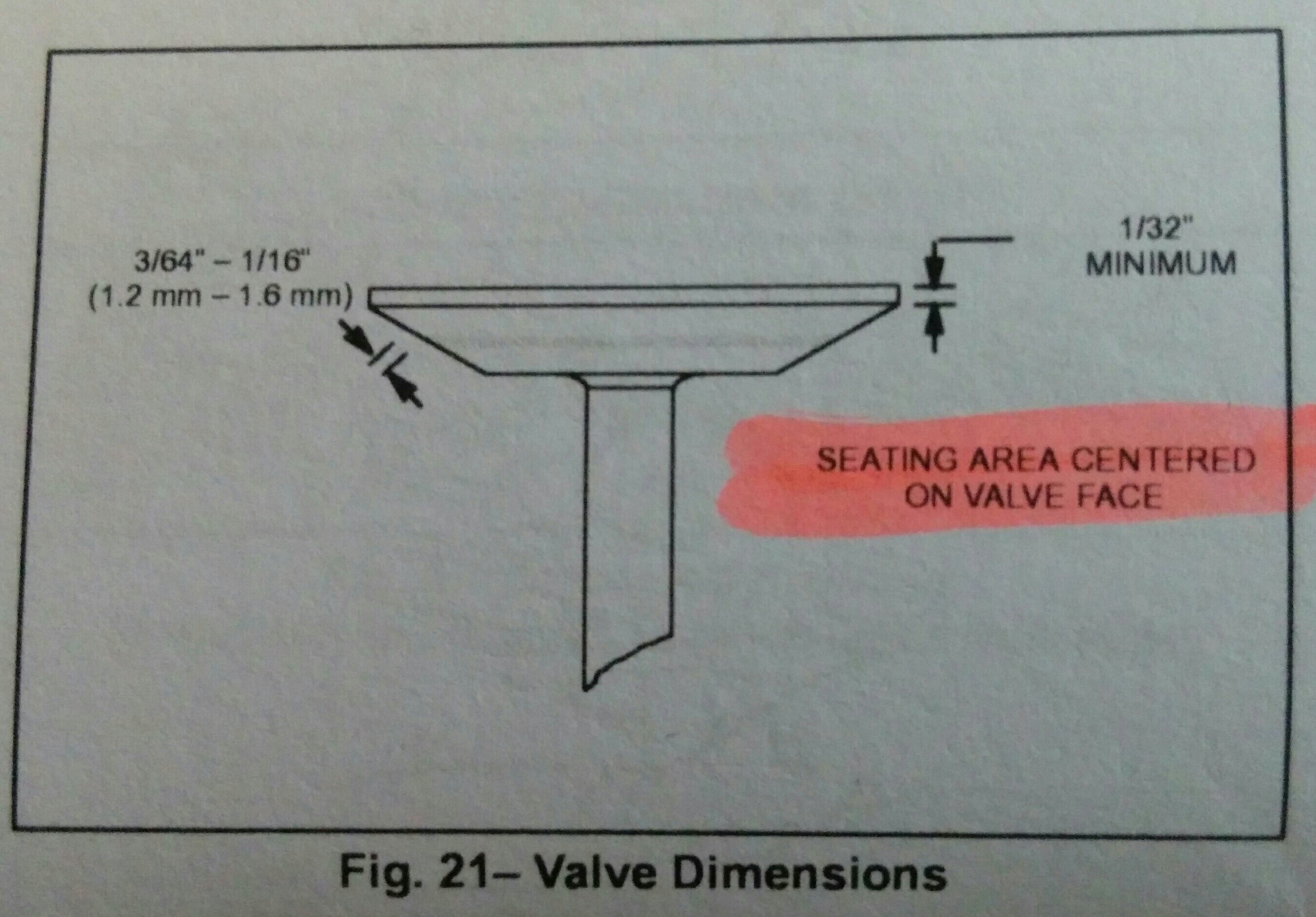

Engine: 13 HP GX390 clone - a lot of mods done to it, now about 20+ HP, diy exhaust system

Transmission: Comet Torque Converter system (ATV/snowmobile), axles with keyways custom-made by a gokart specialist

Rear Axle: taken from a chinese quad (Bashan or alike), stock hydraulic breaking system, very large sprocket (water jetted cut-aways for weight reduction)

Front axle: pendulum axle, quad wheel mounts, diy pitman arm & steering links, 8B-1 chain with a 1:3 steering ratio - wheels to steering wheel - by means of sprockets, 15° caster

Steering Wheel: Alloy RAID, throttle paddle for right thump, hydraulic brake cylinder to be activated by left hand, digital rev-meter, oil temp. gauge to come.

Foot rests: pegs talen from quad, aluminium sheets

More pictures and information at www.WurstExpress.tk , have fun! (also in English)

Cheers,

Fred

Specs

Chassis: 20x30x1.5 mm and 20x20x2 mm steel profiles for structural beams, 20x20x1.5 mm for support frame parts

Engine: 13 HP GX390 clone - a lot of mods done to it, now about 20+ HP, diy exhaust system

Transmission: Comet Torque Converter system (ATV/snowmobile), axles with keyways custom-made by a gokart specialist

Rear Axle: taken from a chinese quad (Bashan or alike), stock hydraulic breaking system, very large sprocket (water jetted cut-aways for weight reduction)

Front axle: pendulum axle, quad wheel mounts, diy pitman arm & steering links, 8B-1 chain with a 1:3 steering ratio - wheels to steering wheel - by means of sprockets, 15° caster

Steering Wheel: Alloy RAID, throttle paddle for right thump, hydraulic brake cylinder to be activated by left hand, digital rev-meter, oil temp. gauge to come.

Foot rests: pegs talen from quad, aluminium sheets

More pictures and information at www.WurstExpress.tk , have fun! (also in English)

Cheers,

Fred

How?

How?